CHOOSE A DESTINATION

The Aggregate Pier Measurement Software

Aggregate Pier Measurement software utilizes and manages model pier stiffness data for use during construction.

Aggregate Pier Measurement Software. This software analyzes and compares aggregate compaction of each lift in every pier to the load test pier for deflection activity and plots results onto the client’s foundation plan.

Job Development. Engineering design deflection values are assigned for each lift in an aggregate pier. These values can be determined by evaluating actual data from the job site, validated through a plate load test. This process enables tailoring of ramming effort to the specific soil and groundwater conditions both in plan and cross section view across a project site. Uniform subgrade foundation support can be discretely constructed in holes rather than through mass excavation techniques.

Data Validation. DDI results for a pier can be compared with adjacent pier results and with matrix soil stiffnesses identified in the project geotechnical report.

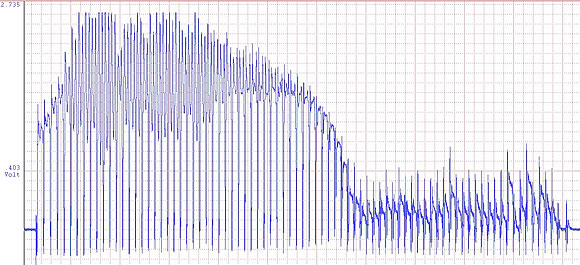

There are two distinct stages which can be evaluated from the Dynamic Deflection Instrument, 1) compaction of the aggregate, and 2) lateral compaction. Compaction of the aggregate is recorded as the initial hump in the graph and is the precursor to lateral bulging.

Lateral bulging is recorded as the continuing vertical advance at a reduced rate. The aggregate particles are being displaced laterally, which is necessary to increase lateral stress in the matrix soil. This is the critical stage because lateral stress and compaction are major factors influencing the effectiveness of rammed aggregate piers, and are what makes this process unique. Lateral stress measurements indicate a sequence of events that includes temporary liquefaction that acts to distribute the stress radially, and the development of radial tension cracks that provide an outlet for excess pore water during compaction of the matrix soil (Handy and White 2006). The friction angle of the matrix soil has been indicated to increase by as much as 15 degrees by the compaction.

Differential Settlement Control - Consistent Foundation Support. Field testing indicates that in variable matrix soil conditions, instrumented piers constructed with the Dynamic Deflection Indicator (DDI) and the Pier Compaction Performance Indicator (PCPI), have a higher degree of modulus consistency than piers constructed without the instrumentation package.

Field testing was conducted with 4 constructed piers. The piers were constructed within an area of approximately 100 yards, at the same elevation, in a native sand, silt and clay profile. 2 piers were constructed using standard consistent timing of lift compaction (6 seconds per lift, 54 seconds per pier); and 2 piers were constructed with DDI/PCPI control of lift compaction timing. Timing on the DDI/PCPI piers was 49.9 seconds on one pier and 65.9 seconds on the other (considerably more groundwater was encountered in the second pier in this pair, than the first one in this pair); resulting in a 34.8% difference of input compaction time on the DDI/PCPI piers.

The piers were subsequently loaded, and the modulus values at 15,300 pounds/square foot (psf), were compared by pier pair. The two consistent timing piers exhibited a variation of 29%, and the two DDI/PCPI piers exhibited a variation of 7% at 15,300 psf.

Thus the DDI/PCPI piers were constructed to a more consistent structural support level.

Archival Data. The model pier deflection values along with the data from the compaction construction work is electronically saved for future review of the work conducted, either for research or liability control purposes